The 400th ASG4X4 200 Series LandCruiser was always going to be something special… being the bosses rig meant it had to be extra special.

VEHICLES 200 Series LandCruiser

With ASG4X4 approaching its 400th dual-cab conversion on the 200 Series LandCruiser, the company’s boss, James, decided he’d set aside build 400 for himself.

It had to show off everything he’d learned over his many years in the conversion business and reflect his passion for the LandCruiser; a passion that began when he was a kid and his father purchased a 60 Series ‘Cruiser.

More than that, it couldn’t just be an over-blown project vehicle that was more about show than go, James wanted something that could take he and his family around the country – it had to be practical, but it also had to look good. According to James, he had a clear idea of what he did and didn’t want from his LandCruiser. And it all started with the colour – James wanted to go retro.

With Toyota’s iconic paint code 4E9 unavailable on the 200 Series LandCruiser in Australia, James decided he’d have the vehicle resprayed. “The majority of the interior would be out for the conversion anyway, so why not go one step further, remove the rest and completely respray it,” he told Unsealed 4X4. To complete the look, James had custom decals designed, inspired by the striping decals from the 60 Series LandCruiser.

WORDS BY TRENT WEBSTER, IMAGES BY MIKE TURGOOSE

Stretched and loaded LandCruiser 200

Details matter most

Weight distribution, as we all know, is critical when touring, so the chassis was extended 650mm in order to get the rear axle closer to the centre of the canopy. Strengthening work was undertaken on the chassis and rear differential too; all essential when increasing the GVM from 3350kg to 4490kg.

For the suspension setup, James went with Lovells Special Products who supplied a set of Lovells GVM-upgrade-rated coils and paired them with that company’s first-ever set of remote reservoir shocks. Superior Engineering upper control arm were fitted after the lift to correct the camber and castor angles, while airbag helper springs have also been fitted.

“We’ve lifted the truck about 40mm, and that’s left it feeling really well balanced. I’ve had a few different suspension setups over the years, but so far, this is setup is handling incredibly well,” James said.

While up on the hoist, the 45-litre factory-fit auxiliary tank was removed and a 180-litre Brown Davis replacement tank installed. With 270 litres of diesel onboard, the vehicles touring range has been increased to more than 1000km when fully loaded and a trailer hooked up.

For protection whilst touring, there’s a TJM T13 front bar and side rails mated to a set of custom ASG4X4 full-length side steps. For underbody protection, James fitted a set of Brown Davis bash plates.

To light up the track, James opted for the newly-released next-generation Lightforce HTX2 lights. There’s a lightbar on the roof and ROK lights around the vehicle; and when they’re on it’s like daylight, James told us.

Baby’s got back…

James went with a Trig Point canopy to match the OEM styled conversion. And to ensure the colour was spot on, the team at Trig Point requested a sample panel be sent directly from the ASG paint shop. “The guys explained that they see a variation in colour from year to year, model to model so getting an actual sample is always the best option,” James said.

Two spare tyre mounts were fitted to the rear of the canopy for remote touring and the integrated canopy roof rack matches height with the platform on the cabin creating even more storage options. “The slam-shut latches and central locking have to be the two best features of the canopy.” James told Unsealed 4X4. “Close the door and walk away…no more walking around checking all the handles are locked”.

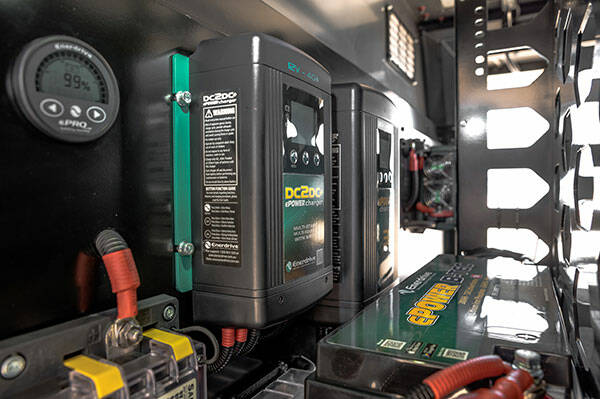

The interior fit-out of the canopy is ever-changing. The original fit out has already been removed, with a new one designed by RV Storage Solutions currently being installed. The one aspect of the canopy setup that won’t be changing, James said, is the power system; he went with an Enerdrive designed system and couldn’t be happier.

Running a ‘large’ capacity upright fridge, a 200Ah Lithium was installed to make sure the beers are always cold. To keep it all charged, James went with a 120W Solar panel on the canopy’s roof hooked up to a 40A DC2DC. For when he’s not driving, or in poor weather, he added a 40A 240V charger. A 2000W inverter was also installed in the back, mainly for charging electronics, but it’s big enough to cover most power tools and coffee machines as well, he told us. To finish it off, an ePro Battery Monitor was fitted. “It shows in, out and time remaining […] and I really don’t think you need any more than that in the canopy,” James said.

Power and performance

With the touring essentials added and knowing he would be racking up some serious kilometres with the camper attached, a power upgrade was the final step in completing his tourer. James turned to Safari 4X4 Engineering and their Armax performance products. The Armax high-flow snorkel and ECU unit have both been fitted. The team from Safari then set about tuning the new setup for maximum performance while ensuring ultimate reliability.

With only a few thousand kilometres on the clock, James reckons he wants to go on a few trips before deciding if he’s done enough, but what’s he think about it, so far? “The best way to describe it, and only ‘Cruiser drivers will get this, it’s like you’ve got a second Eco/Power switch, but it’s Power/Power. That’s how much difference it has made”.

In the end

One thing is certain about James’ stretched 200 Series (dubbed ST200) and that is the colour has divided opinions. Love it or hate it you have to agree, James has built himself one incredibly capable tourer, and a 400th build worthy of the iconic 4E9 paint job.

The 400th ASG4X4 200 Series LandCruiser was always going to be something special… being the bosses rig meant it had to be extra special.

Stretched and loaded LandCruiser 200

With ASG4X4 approaching its 400th dual-cab conversion on the 200 Series LandCruiser, the company’s boss, James, decided he’d set aside build 400 for himself.

It had to show off everything he’d learned over his many years in the conversion business and reflect his passion for the LandCruiser; a passion that began when he was a kid and his father purchased a 60 Series ‘Cruiser.

More than that, it couldn’t just be an over-blown project vehicle that was more about show than go, James wanted something that could take he and his family around the country – it had to be practical, but it also had to look good. According to James, he had a clear idea of what he did and didn’t want from his LandCruiser. And it all started with the colour – James wanted to go retro.

With Toyota’s iconic paint code 4E9 unavailable on the 200 Series LandCruiser in Australia, James decided he’d have the vehicle resprayed. “The majority of the interior would be out for the conversion anyway, so why not go one step further, remove the rest and completely respray it,” he told Unsealed 4X4. To complete the look, James had custom decals designed, inspired by the striping decals from the 60 Series LandCruiser.

WORDS BY TRENT WEBSTER, IMAGES BY MIKE TURGOOSE

VEHICLES 200 Series LandCruiser

While up on the hoist, the 45-litre factory-fit auxiliary tank was removed and a 180-litre Brown Davis replacement tank installed. With 270 litres of diesel onboard, the vehicles touring range has been increased to more than 1000km when fully loaded and a trailer hooked up.

For protection whilst touring, there’s a TJM T13 front bar and side rails mated to a set of custom ASG4X4 full-length side steps. For underbody protection, James fitted a set of Brown Davis bash plates.

To light up the track, James opted for the newly-released next-generation Lightforce HTX2 lights. There’s a lightbar on the roof and ROK lights around the vehicle; and when they’re on it’s like daylight, James told us.

Details matter most

Weight distribution, as we all know, is critical when touring, so the chassis was extended 650mm in order to get the rear axle closer to the centre of the canopy. Strengthening work was undertaken on the chassis and rear differential too; all essential when increasing the GVM from 3350kg to 4490kg.

For the suspension setup, James went with Lovells Special Products who supplied a set of Lovells GVM-upgrade-rated coils and paired them with that company’s first-ever set of remote reservoir shocks. Superior Engineering upper control arm were fitted after the lift to correct the camber and castor angles, while airbag helper springs have also been fitted.

“We’ve lifted the truck about 40mm, and that’s left it feeling really well balanced. I’ve had a few different suspension setups over the years, but so far, this is setup is handling incredibly well,” James said.

The interior fit-out of the canopy is ever-changing. The original fit out has already been removed, with a new one designed by RV Storage Solutions currently being installed. The one aspect of the canopy setup that won’t be changing, James said, is the power system; he went with an Enerdrive designed system and couldn’t be happier.

Running a ‘large’ capacity upright fridge, a 200Ah Lithium was installed to make sure the beers are always cold. To keep it all charged, James went with a 120W Solar panel on the canopy’s roof hooked up to a 40A DC2DC. For when he’s not driving, or in poor weather, he added a 40A 240V charger. A 2000W inverter was also installed in the back, mainly for charging electronics, but it’s big enough to cover most power tools and coffee machines as well, he told us. To finish it off, an ePro Battery Monitor was fitted. “It shows in, out and time remaining […] and I really don’t think you need any more than that in the canopy,” James said.

Baby’s got back…

James went with a Trig Point canopy to match the OEM styled conversion. And to ensure the colour was spot on, the team at Trig Point requested a sample panel be sent directly from the ASG paint shop. “The guys explained that they see a variation in colour from year to year, model to model so getting an actual sample is always the best option,” James said.

Two spare tyre mounts were fitted to the rear of the canopy for remote touring and the integrated canopy roof rack matches height with the platform on the cabin creating even more storage options. “The slam-shut latches and central locking have to be the two best features of the canopy.” James told Unsealed 4X4. “Close the door and walk away…no more walking around checking all the handles are locked”.

Power and performance

With the touring essentials added and knowing he would be racking up some serious kilometres with the camper attached, a power upgrade was the final step in completing his tourer. James turned to Safari 4X4 Engineering and their Armax performance products. The Armax high-flow snorkel and ECU unit have both been fitted. The team from Safari then set about tuning the new setup for maximum performance while ensuring ultimate reliability.

With only a few thousand kilometres on the clock, James reckons he wants to go on a few trips before deciding if he’s done enough, but what’s he think about it, so far? “The best way to describe it, and only ‘Cruiser drivers will get this, it’s like you’ve got a second Eco/Power switch, but it’s Power/Power. That’s how much difference it has made”.

In the end

One thing is certain about James’ stretched 200 Series (dubbed ST200) and that is the colour has divided opinions. Love it or hate it you have to agree, James has built himself one incredibly capable tourer, and a 400th build worthy of the iconic 4E9 paint job.